Agricultural Venlo Greenhouse Polycarbonate/Glass Covering for Sale

Description

Basic Info.

| Model NO. | HJ-P27 |

| Layer | Single |

| Frame | Hot Galvanized Steel |

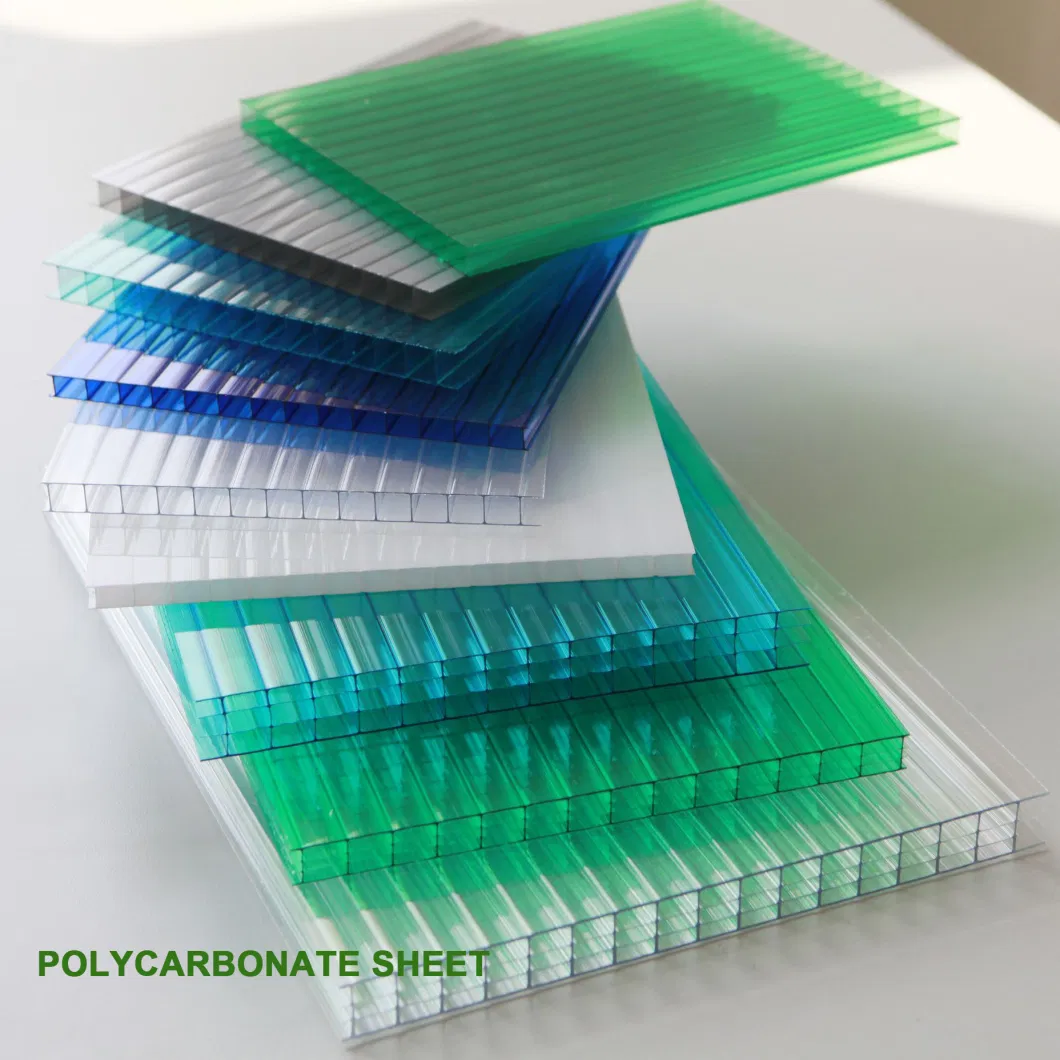

| Covering Material | Polycarbonate Sheet |

| Service | After-Sale Service, Technical Service |

| Optional Systems | Shading, Cooling, Heating, Irrigation, Hydroponic |

| Pillar Spacing | 4m, 6m, 8m or Customized |

| Gutter Height | 3m-5m or Customized |

| Span Width | 8m-12m or Customized |

| Name | Venlo Multi Span PC Greenhouse |

| Transport Package | Steel Tubes by Wires, Accessories by Cartons |

| Specification | Customized |

| Trademark | HUIJING |

| Origin | Shandong, China |

| HS Code | 940690 |

| Production Capacity | 100000sqm/Year |

Packaging & Delivery

Package Size 500.00cm * 200.00cm * 200.00cm Package Gross Weight 15000.000kgProduct Description

HUIJING ONE-STOP GREENHOUSE SOLUTION

Huijing Greenhouse is Located in Weifang city, Shandong Province.It has focused on greenhouse designing, manufacturing and construction for more than 10 years.Greenhouses are often used for growing vegetables, fruits, flowers, and medical herbs, etc., also have applications in exhibitions, experiments, restaurants, entertainment.

GREENHOUSE TYPE

GREENHOUSE SPECIFICATIONS

| HUIJING GREENHOUSE SOLUTION | ||

| Basic Parameters | Wind Load | 0.5KN/m² |

| Snow Load | 0.3KN/m² | |

| Greenhouse constant load | 15kg/m² | |

| Maximum drainage capacity | 140mm/h | |

| Specifications | Span Width | 6.0 - 12.0m or customized |

| Pillar Spacing | 4.0m, 4.5m, 6.0m, 8.0m | |

| Gutter Height | 3.0m - 5.0m or customized | |

| Frame Structure | Hot dip galvanized steel tubes | |

| Covering Materials | PE/PO/PEP film/Polycarbonate sheet/Glass | |

| Optional systems | Ventilation System | Shading System |

| Cooling System | Heating System | |

| Irrigation & Fertilizing System | Benches System | |

| Hydroponics System | Lighting system | |

| Automatic Control System | Other customized equipment | |

| We will make design proposal as customers specific requirements. | ||

GREENHOUSE SYSTEMS

1. Frame StructureHot dip galvanized steel frame has excellent performance of high strength, strong resistance to wind and snow, and good anti-corrosion. The quality is guaranteed for 20 years.2. Covering Material

PO / PE film: 80-200 micron, anti-drip, anti-UV, quality assurance for 3-5 years.Polycarbonate sheet: 6mm/8mm/10mm thickness, double layer hollow, anti-UV, anti-drip, good light transmittance performance, good thermal insulation performance, excellent strength, rigidity, hardness, toughness and crack resistance, quality assurance for 10 years.

Hollow glass: beautiful appearance, good light transmittance performance, thermal insulation performance is equivalent to polycarbonate sheet, quality assurance for 10 years.Single-layer glass: beautiful appearance, excellent light transmittance performance, thermal insulation performance is not as good as polycarbonate sheet, quality assurance for 10 years.

3. Ventilation SystemRoofing & Wall Ventilation4. Shading System

(1) Outside Shading System: The main function of the system is to cool and shade in the summer, so that the sunlight diffuses into the greenhouse to ensure that the crop is protected from glare of the sun. Because it blocks a large amount of light, it effectively reduces the accumulation of heat inside the greenhouse, which generally reduces the greenhouse temperature by 4 °C to 6 °C.(2) Inside Shading and Insulation System: When the inside shading net is closed, two separate spaces are formed in the greenhouse, which can effectively prevent the formation of mist and dripping in the greenhouse. In the winter and night, the inside shading net can effectively prevent the heat inside the greenhouse from overflowing through radiation or heat exchange, thus reducing energy consumption and reducing greenhouse operating costs.

5. Cooling SystemCooling pad + Exaust fans: The cooling is achieved by the principle of evaporation and cooling of water. The special wet cooling pad can ensure that the water evenly wets the entire wet curtain wall. When the air penetrates the wet curtain medium, it exchanges heat with the water vapor on the surface of the wet medium to achieve humidification and cooling of the air.

6. Heating SystemOptional:(1) Coal-fired or gas-fired boiler + Spiral finned tube (2) Coal-fired or gas-fired boiler + heating fans(3) Electric heating fans

7. Bench System

Moving bench: The bench bracket is made of hot-dip galvanized steel pipes. The bench frame is made of angle steel and aluminum alloy.

8. Soilless Cultivation System

Hydroponics System, Sustrate cultivation system

9. Irrigation & Fertilization SystemDrip irrigation, fogging spraying, mobile sprinkler, etc.10. Other SystemsLighting systemAutomatic control systemAgricultural techinical service

PACKING & SHIPPING

1. Steel tubes are nuded and tied up by wires.2. Accessories and parts are packed in cartons.3. All goods are loaded in containers and transported by ship or train

OUR SERVICE

1. Project Design: We will make design proposals of greenhouse solution as customers requirement.2. Competitive Price: With rich manufacturing and sales experience, we can quote quickly and competitively.3. Factory Visit: We warmly welcome customers to visit our company to see our production and quality.4. Samples Supply: We can send samples to customers as required.5. Quality Control: We'll guarantee to supply products strictly as customer's quality requirements. 6. After-sales service: We'll supply installation instruction with the goods, on-line service. We also can dispatch technicians overseas for installation and usage guidance.

Our Contact